Wow, it's taken some time but it's finally done.

Here's what the final print looked like.

The print took about an hour. The material used is ABS plastic because that's the only plastic I have at the moment. The bottom half looks great and everything seems in line. Just after half way through, it looks like there may have been a Y-axis problem and it's gone in slightly. Then about 3/4 of the way though gaps start appearing The most evident it the tail, there's about 3-4 lines where that section has shifted. I'm not really sure what to make of it, but the X-axis, seems to be fine, it's the Y-axis which may have a problem. This is the 4-5 test print.

Here are a few of the other test prints that didn't quite work out.

This was the beginning of some pliers. As you can see something went horribly wrong. I couldn't tell what was going on and where it was failing so I tried printing out a simple bracelet

This is meant to be a stretchable bracelet, but it clearly doesn't look like it. I must have had an incorrect setting when I built the instruction. It's actually not complete. I stopped it because the gear connected to the extruder had fallen off, most likely because it wasn't screwed on tight. Overall, this was looking to be a good print. The X, Y and Z axis had been checked, all that was missing was the extruder.

There was one more print before this just after the failed duck. It's exactly the same print as this one, but the first few seconds of printing it out already looked really wrong. The lines were everywhere and very uneven. I had fixed the X axis, but I had completely forgotten about the Y. After checking it out and the Z axis, that's what popped out.

Here are the ducks side by side. Can you tell which was the first print and which one was the successful print. It's pretty much been because I haven't tightened the screws on the stepper motors enough. It's all thanks to the plastic that has made me afraid of tightening anything together. I think the Y axis needs to be tightened a little more, and then everything should run a little smoother. I'm hoping everything will continue to run smoothly.

Now, what to print next, thingiverse, here I come.

Saturday, 21 April 2012

Friday, 20 April 2012

First test print - a dead duck

The first test print looked as though it was going good, but it soon started to fail.

Here it is in all it's glory.

I've narrowed the problem to the x axis malfunctioning. The part joining the stepper motor to the belt came loose. That's why the head of the duck looks like it's had it's face blown off with a shotgun. The Y axis continued to work and the plastic carried on melting onto the top.

There's also a mysterious hole in the front. Is it meant to be like that? I don't have access to the computer generated 3D model because it's just a test print file that BFB provide. I'm guessing there's still another problem hidden away somewhere, unless it's also related to the X-axis problem. We'll see a little later.

Here it is in all it's glory.

I've narrowed the problem to the x axis malfunctioning. The part joining the stepper motor to the belt came loose. That's why the head of the duck looks like it's had it's face blown off with a shotgun. The Y axis continued to work and the plastic carried on melting onto the top.

There's also a mysterious hole in the front. Is it meant to be like that? I don't have access to the computer generated 3D model because it's just a test print file that BFB provide. I'm guessing there's still another problem hidden away somewhere, unless it's also related to the X-axis problem. We'll see a little later.

3D printer - it's alive!!

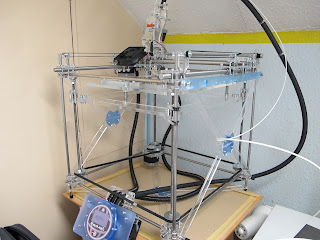

Yes, the printer is complete..... ish

I'm very sure that there are parts still not finished or loose. If you can see in this picture, there are 2 blue bars, one across the top right of my machine and one at the back left. The one across the top is because when I was tightening the Y-axis belt, I must have been too tight and it altered the length to be ever to slightly short so I've put the jig there to hopefully stop it from getting any shorter and maybe push it apart to the correct length. It's not going to work, but at least it's not too far out. The one at the back is because the motors or something else was in the way when I had to tighten the corner posts to the poles and the lower one likes to move so the jig is there to stop it from moving away. It's worked so far but I'd like to attach a more permanent feature later. The wiring was a bit of a nightmare. There's no pictures or real description as to where the conduits are meant to go and if there are, the picture is too close up to the object and you can't tell where it is, or the description is just too vague. What also doesn't seem to want to fit are the big M6 bolts that go into the build platform. It's creating a new screw groove, but it feels like it's about to break, and I'm not really keen on risking it at the moment. I'll try to deal with it later, but for now, it's just going to have to sit like that.

Something they must really need to change is the placement of the control panel. the conduit is clearly in the way of the Z belt. I've been moving it around to try and find a better place for it, but even looking at the design of it, It should go somewhere else and not there.

I'm very sure that there are parts still not finished or loose. If you can see in this picture, there are 2 blue bars, one across the top right of my machine and one at the back left. The one across the top is because when I was tightening the Y-axis belt, I must have been too tight and it altered the length to be ever to slightly short so I've put the jig there to hopefully stop it from getting any shorter and maybe push it apart to the correct length. It's not going to work, but at least it's not too far out. The one at the back is because the motors or something else was in the way when I had to tighten the corner posts to the poles and the lower one likes to move so the jig is there to stop it from moving away. It's worked so far but I'd like to attach a more permanent feature later. The wiring was a bit of a nightmare. There's no pictures or real description as to where the conduits are meant to go and if there are, the picture is too close up to the object and you can't tell where it is, or the description is just too vague. What also doesn't seem to want to fit are the big M6 bolts that go into the build platform. It's creating a new screw groove, but it feels like it's about to break, and I'm not really keen on risking it at the moment. I'll try to deal with it later, but for now, it's just going to have to sit like that.

Something they must really need to change is the placement of the control panel. the conduit is clearly in the way of the Z belt. I've been moving it around to try and find a better place for it, but even looking at the design of it, It should go somewhere else and not there.

Monday, 16 April 2012

3D printer madness

Hazzar the missing parts have arrived. My guess was right and the parts did arrive to me today.

I've pretty much built as much as I could without those 4 metal rods and 6 M6 bolts. It's amazing that I had to stop everything because of a small bag of missing parts.

The build has progressed smoothly, I haven't broken anything yet but I have lost a few M3 nuts and washers, but I'm assuming that they've got more then enough to cover.

The instructions don't get any better then the beginning. It seems that the different sections have been written by different people. Building the hot end had a different style of writing, and then building the extruder had another one which hardly had any writing and I had to rely on the pictures and a lot of guess work. it sort of ended up all right, but I've still got some way to go to finish this thing off.

Anyway, back to building my 3D printer.

Thursday, 12 April 2012

The start of my 3D printer

I've gone and bought a 3D printer from bits from bytes. The idea is not just to continue my craze with cosplay stuff..... or start to be more accurate, but also to make some pieces to help around the house that I just can't find anywhere, or it's too expensive.

I've gone and bought the repman 3.2 from bitsfrombytes.com. I've decided to go as cheap as possible and buy the single extruder and assemble my own hot end. I'm on a tight budget, so I can't go lashing out on the highest end product. I decided on getting this printer because the build area is much larger then the others I've seen. I just hope I haven't made a mistake in buying this.

I've received my printer in parts today and it's already starting off on a bad foot. There's a bag of parts missing from the box. The check list has it ticked off, but it's just not there. I'm going to carry on building what I can even without this one part.

I'm already part way through and the instructions are not that good. On most sections there's a 3D model that you can manipulate a bit to look around to see what goes where, but the instructions don't seem to be written in understandable English. I'm a programmer, but even then, it seems the instructions are wrong. A few of the parts listed aren't even needed in that section.

What's gotten me really worried is the test piece that was they give you to try out breaking the plastic to see what sort of pressure you can use before it breaks. This should prevent you from making too much of a mistake........ I broke the test piece very easily which means that I'll have to gingerly put everything together and hope that it stays put without getting a real feeling of tightening all the nuts and bolts. This is a little scary. I wonder if I can print my own parts? or should I build myself a laser CNC machine and make some spare parts. Hmmmm, that's only if I can get this thing to work.

The support is quite prompt. I've e-mailed them and they've already replied and said that the part I need is in the post. Sadly, it's a Thursday night, so it should go out tomorrow..... and I'll get it on Monday.

Anyway, back to building.

I've gone and bought the repman 3.2 from bitsfrombytes.com. I've decided to go as cheap as possible and buy the single extruder and assemble my own hot end. I'm on a tight budget, so I can't go lashing out on the highest end product. I decided on getting this printer because the build area is much larger then the others I've seen. I just hope I haven't made a mistake in buying this.

I've received my printer in parts today and it's already starting off on a bad foot. There's a bag of parts missing from the box. The check list has it ticked off, but it's just not there. I'm going to carry on building what I can even without this one part.

I'm already part way through and the instructions are not that good. On most sections there's a 3D model that you can manipulate a bit to look around to see what goes where, but the instructions don't seem to be written in understandable English. I'm a programmer, but even then, it seems the instructions are wrong. A few of the parts listed aren't even needed in that section.

What's gotten me really worried is the test piece that was they give you to try out breaking the plastic to see what sort of pressure you can use before it breaks. This should prevent you from making too much of a mistake........ I broke the test piece very easily which means that I'll have to gingerly put everything together and hope that it stays put without getting a real feeling of tightening all the nuts and bolts. This is a little scary. I wonder if I can print my own parts? or should I build myself a laser CNC machine and make some spare parts. Hmmmm, that's only if I can get this thing to work.

The support is quite prompt. I've e-mailed them and they've already replied and said that the part I need is in the post. Sadly, it's a Thursday night, so it should go out tomorrow..... and I'll get it on Monday.

Anyway, back to building.

Subscribe to:

Comments (Atom)