Wow, it's taken some time but it's finally done.

Here's what the final print looked like.

The print took about an hour. The material used is ABS plastic because that's the only plastic I have at the moment. The bottom half looks great and everything seems in line. Just after half way through, it looks like there may have been a Y-axis problem and it's gone in slightly. Then about 3/4 of the way though gaps start appearing The most evident it the tail, there's about 3-4 lines where that section has shifted. I'm not really sure what to make of it, but the X-axis, seems to be fine, it's the Y-axis which may have a problem. This is the 4-5 test print.

Here are a few of the other test prints that didn't quite work out.

This was the beginning of some pliers. As you can see something went horribly wrong. I couldn't tell what was going on and where it was failing so I tried printing out a simple bracelet

This is meant to be a stretchable bracelet, but it clearly doesn't look like it. I must have had an incorrect setting when I built the instruction. It's actually not complete. I stopped it because the gear connected to the extruder had fallen off, most likely because it wasn't screwed on tight. Overall, this was looking to be a good print. The X, Y and Z axis had been checked, all that was missing was the extruder.

There was one more print before this just after the failed duck. It's exactly the same print as this one, but the first few seconds of printing it out already looked really wrong. The lines were everywhere and very uneven. I had fixed the X axis, but I had completely forgotten about the Y. After checking it out and the Z axis, that's what popped out.

Here are the ducks side by side. Can you tell which was the first print and which one was the successful print. It's pretty much been because I haven't tightened the screws on the stepper motors enough. It's all thanks to the plastic that has made me afraid of tightening anything together. I think the Y axis needs to be tightened a little more, and then everything should run a little smoother. I'm hoping everything will continue to run smoothly.

Now, what to print next, thingiverse, here I come.

Saturday, 21 April 2012

Friday, 20 April 2012

First test print - a dead duck

The first test print looked as though it was going good, but it soon started to fail.

Here it is in all it's glory.

I've narrowed the problem to the x axis malfunctioning. The part joining the stepper motor to the belt came loose. That's why the head of the duck looks like it's had it's face blown off with a shotgun. The Y axis continued to work and the plastic carried on melting onto the top.

There's also a mysterious hole in the front. Is it meant to be like that? I don't have access to the computer generated 3D model because it's just a test print file that BFB provide. I'm guessing there's still another problem hidden away somewhere, unless it's also related to the X-axis problem. We'll see a little later.

Here it is in all it's glory.

I've narrowed the problem to the x axis malfunctioning. The part joining the stepper motor to the belt came loose. That's why the head of the duck looks like it's had it's face blown off with a shotgun. The Y axis continued to work and the plastic carried on melting onto the top.

There's also a mysterious hole in the front. Is it meant to be like that? I don't have access to the computer generated 3D model because it's just a test print file that BFB provide. I'm guessing there's still another problem hidden away somewhere, unless it's also related to the X-axis problem. We'll see a little later.

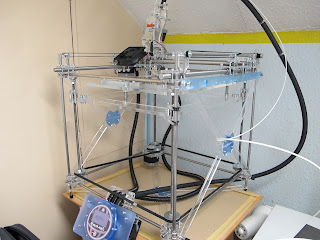

3D printer - it's alive!!

Yes, the printer is complete..... ish

I'm very sure that there are parts still not finished or loose. If you can see in this picture, there are 2 blue bars, one across the top right of my machine and one at the back left. The one across the top is because when I was tightening the Y-axis belt, I must have been too tight and it altered the length to be ever to slightly short so I've put the jig there to hopefully stop it from getting any shorter and maybe push it apart to the correct length. It's not going to work, but at least it's not too far out. The one at the back is because the motors or something else was in the way when I had to tighten the corner posts to the poles and the lower one likes to move so the jig is there to stop it from moving away. It's worked so far but I'd like to attach a more permanent feature later. The wiring was a bit of a nightmare. There's no pictures or real description as to where the conduits are meant to go and if there are, the picture is too close up to the object and you can't tell where it is, or the description is just too vague. What also doesn't seem to want to fit are the big M6 bolts that go into the build platform. It's creating a new screw groove, but it feels like it's about to break, and I'm not really keen on risking it at the moment. I'll try to deal with it later, but for now, it's just going to have to sit like that.

Something they must really need to change is the placement of the control panel. the conduit is clearly in the way of the Z belt. I've been moving it around to try and find a better place for it, but even looking at the design of it, It should go somewhere else and not there.

I'm very sure that there are parts still not finished or loose. If you can see in this picture, there are 2 blue bars, one across the top right of my machine and one at the back left. The one across the top is because when I was tightening the Y-axis belt, I must have been too tight and it altered the length to be ever to slightly short so I've put the jig there to hopefully stop it from getting any shorter and maybe push it apart to the correct length. It's not going to work, but at least it's not too far out. The one at the back is because the motors or something else was in the way when I had to tighten the corner posts to the poles and the lower one likes to move so the jig is there to stop it from moving away. It's worked so far but I'd like to attach a more permanent feature later. The wiring was a bit of a nightmare. There's no pictures or real description as to where the conduits are meant to go and if there are, the picture is too close up to the object and you can't tell where it is, or the description is just too vague. What also doesn't seem to want to fit are the big M6 bolts that go into the build platform. It's creating a new screw groove, but it feels like it's about to break, and I'm not really keen on risking it at the moment. I'll try to deal with it later, but for now, it's just going to have to sit like that.

Something they must really need to change is the placement of the control panel. the conduit is clearly in the way of the Z belt. I've been moving it around to try and find a better place for it, but even looking at the design of it, It should go somewhere else and not there.

Monday, 16 April 2012

3D printer madness

Hazzar the missing parts have arrived. My guess was right and the parts did arrive to me today.

I've pretty much built as much as I could without those 4 metal rods and 6 M6 bolts. It's amazing that I had to stop everything because of a small bag of missing parts.

The build has progressed smoothly, I haven't broken anything yet but I have lost a few M3 nuts and washers, but I'm assuming that they've got more then enough to cover.

The instructions don't get any better then the beginning. It seems that the different sections have been written by different people. Building the hot end had a different style of writing, and then building the extruder had another one which hardly had any writing and I had to rely on the pictures and a lot of guess work. it sort of ended up all right, but I've still got some way to go to finish this thing off.

Anyway, back to building my 3D printer.

Thursday, 12 April 2012

The start of my 3D printer

I've gone and bought a 3D printer from bits from bytes. The idea is not just to continue my craze with cosplay stuff..... or start to be more accurate, but also to make some pieces to help around the house that I just can't find anywhere, or it's too expensive.

I've gone and bought the repman 3.2 from bitsfrombytes.com. I've decided to go as cheap as possible and buy the single extruder and assemble my own hot end. I'm on a tight budget, so I can't go lashing out on the highest end product. I decided on getting this printer because the build area is much larger then the others I've seen. I just hope I haven't made a mistake in buying this.

I've received my printer in parts today and it's already starting off on a bad foot. There's a bag of parts missing from the box. The check list has it ticked off, but it's just not there. I'm going to carry on building what I can even without this one part.

I'm already part way through and the instructions are not that good. On most sections there's a 3D model that you can manipulate a bit to look around to see what goes where, but the instructions don't seem to be written in understandable English. I'm a programmer, but even then, it seems the instructions are wrong. A few of the parts listed aren't even needed in that section.

What's gotten me really worried is the test piece that was they give you to try out breaking the plastic to see what sort of pressure you can use before it breaks. This should prevent you from making too much of a mistake........ I broke the test piece very easily which means that I'll have to gingerly put everything together and hope that it stays put without getting a real feeling of tightening all the nuts and bolts. This is a little scary. I wonder if I can print my own parts? or should I build myself a laser CNC machine and make some spare parts. Hmmmm, that's only if I can get this thing to work.

The support is quite prompt. I've e-mailed them and they've already replied and said that the part I need is in the post. Sadly, it's a Thursday night, so it should go out tomorrow..... and I'll get it on Monday.

Anyway, back to building.

I've gone and bought the repman 3.2 from bitsfrombytes.com. I've decided to go as cheap as possible and buy the single extruder and assemble my own hot end. I'm on a tight budget, so I can't go lashing out on the highest end product. I decided on getting this printer because the build area is much larger then the others I've seen. I just hope I haven't made a mistake in buying this.

I've received my printer in parts today and it's already starting off on a bad foot. There's a bag of parts missing from the box. The check list has it ticked off, but it's just not there. I'm going to carry on building what I can even without this one part.

I'm already part way through and the instructions are not that good. On most sections there's a 3D model that you can manipulate a bit to look around to see what goes where, but the instructions don't seem to be written in understandable English. I'm a programmer, but even then, it seems the instructions are wrong. A few of the parts listed aren't even needed in that section.

What's gotten me really worried is the test piece that was they give you to try out breaking the plastic to see what sort of pressure you can use before it breaks. This should prevent you from making too much of a mistake........ I broke the test piece very easily which means that I'll have to gingerly put everything together and hope that it stays put without getting a real feeling of tightening all the nuts and bolts. This is a little scary. I wonder if I can print my own parts? or should I build myself a laser CNC machine and make some spare parts. Hmmmm, that's only if I can get this thing to work.

The support is quite prompt. I've e-mailed them and they've already replied and said that the part I need is in the post. Sadly, it's a Thursday night, so it should go out tomorrow..... and I'll get it on Monday.

Anyway, back to building.

Wednesday, 8 February 2012

Arduino - camera time lapse controller

I went out and online to look for a remote control to for my Canon Powershot G12. The most basic which featured one button to just take pictures cost about 10 pounds. However I wanted something that will continuously take pictures for me so that I can create a time lapse video. A remote unit to do that would cost at least 70 pounds. At first I thought that would be fine with all the additional functions that I can do with it, but I still decided to have a look at what it would really do.

What really ticked me off was when I found this site that showed the wiring needed for the 2.5mm jack. Was that all?!! I'm paying money to connect its own ground to its shutter and focus?!? If go to the site, you'll see what I mean.

Seeing that I have a load of electronics lying around, I decided to make my own camera controller.

To test the theory of the site above to see if the wiring is really that simple, I connected wires to a 3 pole 2.5mm jack and just plugged it in to my camera and connected the wires to see what would really happen. Yes, it worked. I controlled the autofocus and the shutter control. So the next thing to do was to connect it up to a tactile push button and control it properly. That worked even better. So I had a fully functioning remote control that will allow me to not touch my camera to take a picture in a fixed position.

The timing of the shots taken are all controlled in the programming of the Arduino. I'm considering adding some sort of display to allow changing the timings to be done without a computer present. Also, a cheaper version of the Arduino so that I can take it out and use it for something else.

Click here to see a simple experiment of the outcome of creating this project. It's watching ice melt so it's going to be a boring watch BUT what you can't see is that it's 2 and a half hours shrunk into just 20 seconds. I set it up to take pictures every 20 seconds. In the video rendering, I made it so that it was 24 frames a second. This way, it would be more compatible with any file format I save the video.

I've got to find something more worthwhile taking a time-lapse photography for!

update: I've been asked to provide my coding for my Arduino to help people out. It's actually a combination of 2 other people's coding. One to get the latch working on a push button and the second is the actual taking pictures with a simple relay/optocoupler. I'm still streamlining it and improving it to make it work better.

so here it is:

int INTERVAL_TM = 7000; // 7 seconds shot interval

int EXPOSURE_TM = 1000; // keep fixed at 500 - 1000

int CAMERA_PIN = 13; // my pin that will trigger the camera

int STARTSTOP_PIN = 3; // a pushbutton to allow start of time lapse

int val; //value of button press

int buttonState; //check variable for change of button press

int on_off = 0; //state of sequence (turned on, turned off)

void setup(){

pinMode(CAMERA_PIN, OUTPUT); //set CAMER_PIN as an output

pinMode(STARTSTOP_PIN, INPUT); //set STARTSTOP_PIN as an input

buttonState = digitalRead(STARTSTOP_PIN); //read value of the button

}

void loop(){

val = digitalRead(STARTSTOP_PIN); // read button value and store it in val

if (val != buttonState) { // if the button state has changed…

if (val == LOW) { // check if the button is pressed…

if (on_off == 0) { // if the sequence is currently off…

on_off = 1; // turn the sequence on

delay(EXPOSURE_TM); // wait the initial period

} else {

on_off = 0; // turn the sequence off

}

}

}

buttonState = val; //switch the button state

if (on_off == 1) { //take some pictures time

digitalWrite(CAMERA_PIN, HIGH); //pressing camera button

delay(EXPOSURE_TM); //doesn't need to be long at all

digitalWrite(CAMERA_PIN, LOW); //let go of camera button

delay(INTERVAL_TM); //interval between shots

}

}

Saturday, 7 January 2012

Zelda Master Sword

It's been quite some time since I've written in this blog. I've been caught up in a few other things..... like Christmas and New Year and some other stuff.

Anyway, here we go again. This time around, it's Link's Master Sword from Zelda Twilight Princess.

Here is it mostly glued together...... I say mostly because it is still missing one vital part to stick together. The blade to the rest of it is not actually stuck down. It still looks impressive as it is now. What you can't see is that the inside, I've added another layer of paper to try and strengthen it.

Here's a closer look at the 3 join points. The funny thing about this pepakura file I had was that the handle, the center section and the blade were separate. It was not designed to come together. What you also can't see is that I've modified the handle by cutting up the top and folding the pieces out so I can glue it securely to the middle section.

This is what the handle and the middle section stuck together looks like without the blade. I'm still wondering how I can glue the blade on so that it will be stronger then just sticking it in and hoping for the best.

Since printing this out and glueing it together, I've actually found some better files which I've seen people actually be able to build a life size Link. It looks quite exciting and and there are pictures of other people who have completed the project so I'm guessing that they haven't had to try and alter the pieces to try and put it together. It's not just the sword, but the shield too.

Next up is to fibre glass it. One of the problems I'm expecting is that it won't be strong enough because I won't be able to fibre glass the inside. Should I apply the fibre glass on the outside with the fibre glass sheets or should I just risk it and see how it fairs with only fibre glass resin? I've got a feeling I might just try the resin and never let it be touched by anyone.

There are a few other details that I need to put in sometime, like the tri-force on the lower part of the blade and also the handle is square. Should I try to round it out somehow? I might stick with the quicker option for the time being and just leave it as it is and do the best I can as quick as I can because I haven't finished one project yet. With no moving parts and a relatively simple looking (hopefully) design, I should be able to sand it down and give it a good look.

Anyway, here we go again. This time around, it's Link's Master Sword from Zelda Twilight Princess.

Here is it mostly glued together...... I say mostly because it is still missing one vital part to stick together. The blade to the rest of it is not actually stuck down. It still looks impressive as it is now. What you can't see is that the inside, I've added another layer of paper to try and strengthen it.

Here's a closer look at the 3 join points. The funny thing about this pepakura file I had was that the handle, the center section and the blade were separate. It was not designed to come together. What you also can't see is that I've modified the handle by cutting up the top and folding the pieces out so I can glue it securely to the middle section.

This is what the handle and the middle section stuck together looks like without the blade. I'm still wondering how I can glue the blade on so that it will be stronger then just sticking it in and hoping for the best.

Since printing this out and glueing it together, I've actually found some better files which I've seen people actually be able to build a life size Link. It looks quite exciting and and there are pictures of other people who have completed the project so I'm guessing that they haven't had to try and alter the pieces to try and put it together. It's not just the sword, but the shield too.

Next up is to fibre glass it. One of the problems I'm expecting is that it won't be strong enough because I won't be able to fibre glass the inside. Should I apply the fibre glass on the outside with the fibre glass sheets or should I just risk it and see how it fairs with only fibre glass resin? I've got a feeling I might just try the resin and never let it be touched by anyone.

There are a few other details that I need to put in sometime, like the tri-force on the lower part of the blade and also the handle is square. Should I try to round it out somehow? I might stick with the quicker option for the time being and just leave it as it is and do the best I can as quick as I can because I haven't finished one project yet. With no moving parts and a relatively simple looking (hopefully) design, I should be able to sand it down and give it a good look.

Subscribe to:

Comments (Atom)